By clicking the “I Accept” button, or by accessing, participating, or submitting any information, or using the Jabil Global Intelligence Portal or any of its associated software, you warrant that you are duly authorized to accept the Global Intelligence Portal Terms and Conditions on behalf of your Company, intending to be legally bound hereby, and your company shall be bound by the terms and provisions of the Global Intelligence Portal Terms and Conditions, accessible under the following link Portal T&Cs.

Global Commodity Intelligence

Q2 2025 | APRIL - JUNE

Global Commodity Intelligence

Q2 2025 | APRIL - JUNE

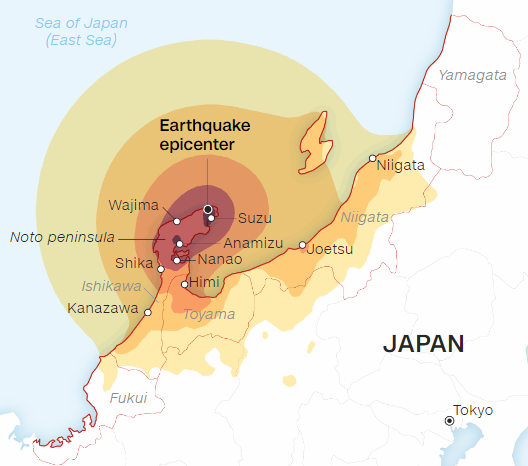

ALERT: 2024 Japan Earthquake - Impact Sustained by Murata Factories in Ishikawa and Toyama Prefectures

William Koh, Director, Supply Chain Management

On January 1, 2024, at 16:10 JST (07:10 UTC), a magnitude 7.6 earthquake, registering 7 on the seismic intensity scale, struck 7 km (4.3 miles) north-northwest of Suzu, located on the Noto Peninsula of Ishikawa Prefecture, Japan. The Noto Peninsula experienced severe damage from the initial earthquake, over 1,000 aftershocks, and a tsunami. This created a devastating impact of 213 deaths, 567 injuries, another 52 people missing, and leaving 2,562 people without homes. This earthquake did not cause major damage to the Shika nuclear plant, although a minor shutdown occurred, which returned to normal operations soon after all inspections were completed.

**Epic Center of Earthquake in north-northwest of Suzu

In our assessment of 25 suppliers for Passive, Connector, Switch, and Relay components, a significant number indicated minimal to no factory impact. However, several suppliers mentioned encountering challenges related to utilities and logistics. Murata experienced the most substantial factory impact, particularly in regions such as Anamizu, Himi, Hakui, Wakura, and Komatsu. Reports also indicated infrastructure damage affecting logistics activities in these areas.

In particular, the soft sediments beneath Anamizu exacerbated the impact by amplifying ground motions. Employee injuries, utility outages, and factory and machine damages were reported.

Other impacted factories and product manufacturers in Murata are:

- Himi: Ceramic filters and resonators.

- Komatsu: Modules, RFID, SAW devices, and related products.

- Wakura: Resin multi-boards

- Hakui: Piezoelectric buzzers, ultrasonic sensors, shock sensors, Picoleaf and CO2 Sensors

Guidance: There will be a potential two-month delivery delay in these factories while the assessments are ongoing.

Key takeaways:

- The earthquake and aftershocks have directly impacted four Murata factories in the Ishikawa and Toyama prefectures.

- The most severely impacted factory is the Anamizu factory, which produces Chip Inductors and Common mode choke coils. Notice of Force Majeure was issued on 15 January. Production will be delayed until the middle of May.

- Impacted commodities from the four other factories are Ceramic filters, Resonators, Buzzers, and several types of Sensors. A potential delivery delay of two months will be expected.

Actions required:

- Review affected parts and work closely with Murata to provide your requirements for the next two months so that critical needs for your business can get prioritized.

- Ask for options from other Murata factories producing the same parts.

- If Murata cannot meet short-term demand, exploring open market stocks for either Murata components or other approved AMLs is recommended.

- If the above actions cannot meet our requirements, work with your customers to approve an alternate source. Additionally, discuss with the Global Commodity Managers to explore potential solutions to alleviate the current supply challenge.

Please do not hesitate to reach out to Kate Zhang, Daniel Poo, or myself if you have any further questions.

William Koh, Director, Supply Chain Management

Back to Top