By clicking the “I Accept” button, or by accessing, participating, or submitting any information, or using the Jabil Global Intelligence Portal or any of its associated software, you warrant that you are duly authorized to accept the Global Intelligence Portal Terms and Conditions on behalf of your Company, intending to be legally bound hereby, and your company shall be bound by the terms and provisions of the Global Intelligence Portal Terms and Conditions, accessible under the following link Portal T&Cs.

Global Mechanicals Intelligence

Global Mechanicals Intelligence

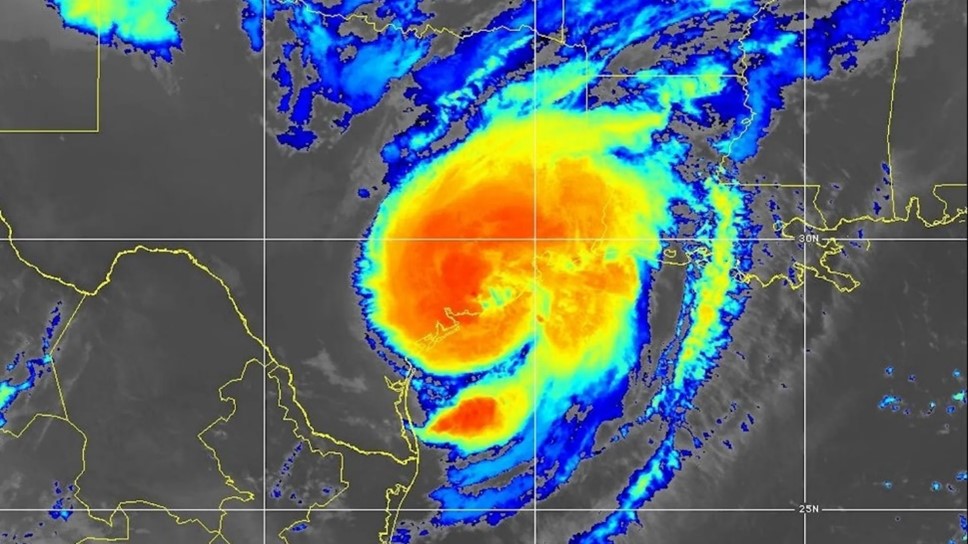

ALERT: Potential Impact of Hurricane Beryl on Petrochemical Production

Andy VanPutte, Senior Director, Supply Chain

Mechanicals+ Global Commodity Management

Hurricane Beryl made landfall on the Gulf Coast of Texas early Monday, July 8th, approximately 85 miles south-southwest of Houston. This region is a critical area for North American petrochemical production, and disruptions there can send shockwaves through global petrochemical supply chains.

Key Facts:

- Dominant Production Hub: The Gulf Coast is home to over 70% of North America's petrochemical production.

- Infrastructure and Capacity: The Gulf Coast region contributes ~20% of the total crude oil production in the US, ~45% of US petroleum refining capacity, and ~50% of US natural gas processing capacity. It also represents over half of US downstream chemical production, with at least 55 major chemical plants.

Potential Impacts:

- Production Disruptions:

- Facility Shutdowns: Some petrochemical plants in Beryl’s forecasted path conducted preemptive temporary shutdowns to protect the safety of personnel and equipment. This could lead to production delays and reduced output.

- Logistical Challenges: The hurricane and subsequent flooding may disrupt transportation networks, including ports, roads, and railways. These lifelines keep raw materials flowing in and finished products moving out, and disruptions can significantly impede operations.

- Supply Chain Effects:

- Raw Material Shortages: Disruptions in petrochemical production can lead to shortages of critical raw materials needed for various industries, including plastics, pharmaceuticals, and automotive.

- Increased Prices: Reduced supply and increased demand pressures can lead to global price surges for petrochemical products and derivatives.

- Global Procurement and Market Dynamics:

- Supplier Reliance: Companies heavily reliant on Gulf Coast suppliers may face challenges securing alternative sources. This could necessitate shifts in procurement strategies to mitigate risks.

- Market Volatility: The global petrochemical market may experience volatility as supply chain disruptions from the Gulf Coast ripple through international markets.

Recommendation:

Conduct a comprehensive risk assessment to evaluate supply chains and identify potential vulnerabilities thoroughly.

Consider factors such as geographical location, reliance on specific suppliers, and the potential impact of natural disasters like hurricanes on production facilities.

Future Impacts

Looking ahead, the potential impact of a major hurricane making landfall on the Gulf Coast remains a significant concern for the petrochemical industry.

Hurricane season runs from June 1 to November 30, with the busiest part between August and October. This year, NOAA forecasters predict above-normal hurricane activity, including four to seven “major” hurricanes. This is due to a confluence of factors, including near-record warm ocean temperatures in the Atlantic Ocean, development of La Nina conditions in the Pacific, reduced Atlantic trade winds, and less wind shear, all of which tend to favor tropical storm formation.

Back to Top